Custom Development

We use a range of software and hardware frameworks to solve complex plant data integration challenges. Our core development is built on C++ and C#, with additional support from languages like Java, JavaScript, Python, SQL, PowerShell, HTML5, and others as project needs evolve.

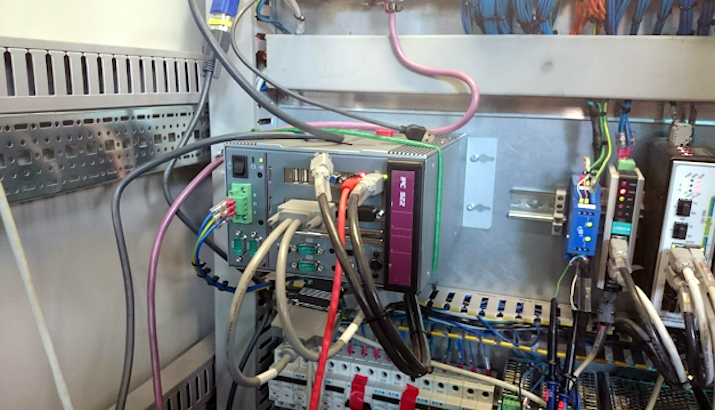

Connecting Systems that are Old and New

With years of experience in industrial protocols, control systems, and plant equipment, we help customers and partners bridge connectivity gaps whether by integrating proprietary or legacy systems with modern platforms or enabling communication between multiple contemporary systems that need to share critical information across the plant.

Consistent Data Standards Across All Systems

Synchronising information naming, engineering units, ranges, and metadata across multiple systems ensures consistent and accurate data interpretation throughout your industrial environment for better system-wide integration and insight.

Real-Time Data Flow Between Systems

Enabling bi-directional flow of live process data and status updates to maintain continuous, reliable communication between systems for enhanced operational visibility and informed decision-making across operations.

Capturing Every Data Point, Even During Outages

Providing buffering and store-and-forward functionality to ensure historical data is captured without gaps when higher-level communication paths are interrupted and only restored later, disruptions that may last seconds, hours, or even days.

Supporting Third-Party Application Integration

Providing standard programmable interfaces that enable broader integration, allowing more third-party applications to access, utilise, and interact with industrial data across diverse systems and platforms.

Seamless Migration of Historical Data

Facilitating the seamless migration of historical plant data from one information repository to another, ensuring data integrity, accessibility, and continuity across modernised or restructured systems.

Custom Developments with the IDX Nexus Framework

Clients who adopt the IDX Nexus Framework benefit from these customised developments, which are consistent and easy to manage. These tailored solutions address specific business requirements while adhering to modern standards for secure and reliable information exchange.

Nexus Connector

When information needs to be exchanged with a system that cannot use an existing IDX Connector, a new connector can be developed to enable the data exchange. Examples of existing connectors include OPC DA Server, OPC DA Client, OPC UA Server, OPC UA Client, MODBUS TCP Server, and MODBUS TCP Client.

Nexus Serial Device

This unit offers a robust hardware and firmware framework built on the ESP32-S3 processor, enabling seamless communication with RS232 or RS485 field equipment. It runs Arduino and FreeRTOS for flexible, reliable industrial device integration across diverse automation environments.

Nexus Universal Gateway Device

This unit delivers a hardware and Arduino firmware framework for communicating with field equipment, designed for integration into a wide range of industrial Ethernet and fieldbus systems via HMS Networks’ Anybus CompactCom modules (PROFIBUS-DP, PROFINET-IRT, Ethernet/IP, EtherCAT, and more).

Nexus Web API

This is a published interface enabling third-party applications to interact with the Nexus Framework. The API continues to grow in functionality as new integration use cases emerge, supporting greater flexibility, extensibility, robust performance, and seamless system interoperability.

Features

Compliant Framework

The framework is standards-based, ensuring broad compatibility, future-proofing, and seamless integration across systems.

Extendable Architecture

Its extendable architecture allows for easy adaptation, supporting evolving technologies, custom requirements, and future system integrations.

Proven Performance

With decades of deployment, this foundational framework is trusted and proven in demanding industrial environments.

Benefits

Reduces implementation and operational costs through efficient integration and minimal disruption to existing systems.

Minimises risks associated with system upgrades and migrations by supporting gradual, controlled transitions.

Enables legacy and modern systems to work together, avoiding costly, disruptive single-phase changeovers.

Case Studies

Wireless freezer monitoring, alarming, and reporting solution

There are numerous benefits to embracing the digitisation of systems and the use of real-time data monitoring, often associated with the…

StarNET HDLC Controller Gateway solves legacy migration challenge

In August 2016, IDX completed the commissioning of its latest StarNET HDLC gateway development implementation which…

Migrating historical data between historians

Organisations that wish to change the data Historians use are often faced with the challenge of what to do with the data…

Let us Build Your Custom Solution

Partner with us to create reliable, future-ready solutions tailored to your plant’s integration needs. We turn complex requirements into practical, maintainable systems that work.

Our expertise lies in establishing, maintaining, and leveraging plant data for business benefit. Through our innovative solutions, we work alongside you to streamline processes, enhance efficiency, and reduce costly downtime.

CONTACT US

Main: +27 (11) 548 9960

Sales: +27 (11) 548 9970

SOCIAL MEDIA

Copyright @2025 Industrial Data Xchange.

All rights reserved.